Our BusinessOur Approach to Energy from Waste(EfW)

Pacific Consultants Co., Ltd. is a leading company with the highest trading volume among Japanese waste management consulting companies. Pacific Consultants Co., Ltd. has a wealth of experience in facility conceptualization, facility planning, facility design, feasibility studies, technical evaluations, construction monitoring, and operational monitoring for waste treatment facilities such as Energy from Waste (EfW) facilities and material recovery facilities.

Energy from Waste (EfW)

SOLUTION

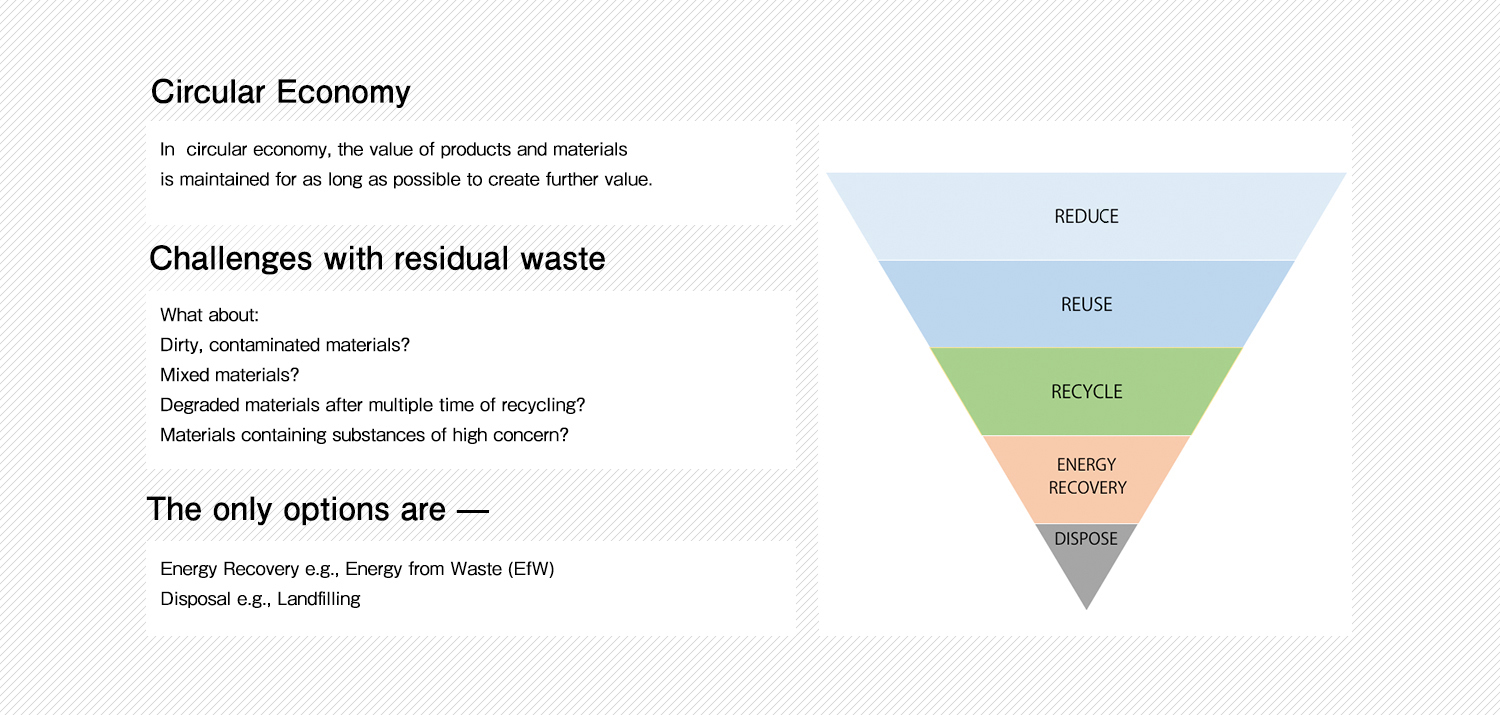

There has been very little success in reversing the trend of the increased generation of MSW, meaning that the world has continued on its course to becoming one “throwaway society”.

While EfW incineration is one of the best solutions for waste volume reduction and energy recovery. Today, around 1,400 EfW facilities are active worldwide.

Smart City Technology

These EfW facilities are to be located and operated in urban areas around the world with safe technology. Our EfW facility will introduce smart city technology and include an education center where students learn about sustainable society.

What is an Energy from Waste (EfW) Facility?

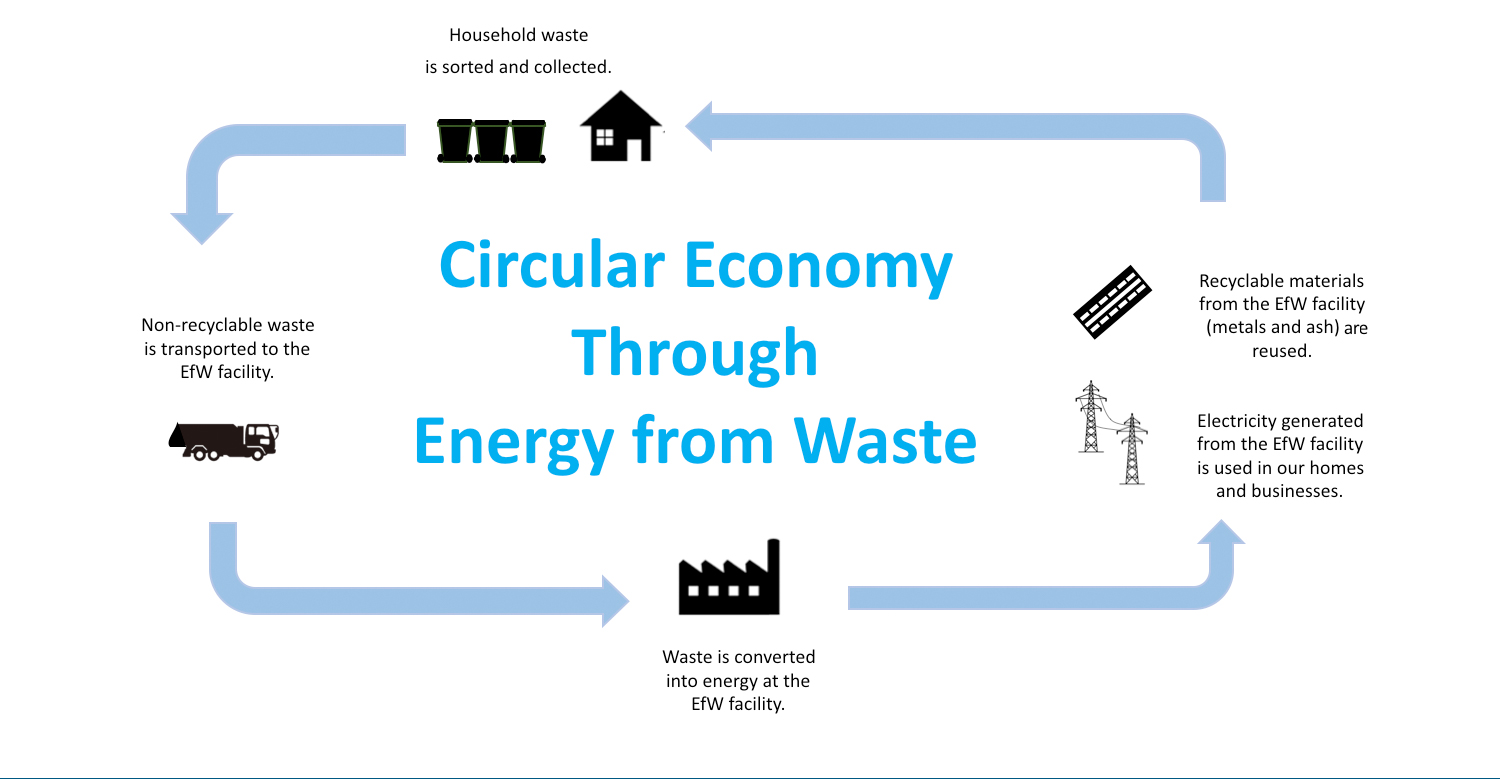

This diagram shows the steps of waste collection and treatment.

PROCESS of EfW

Decade ago, waste incinerators were used to reduce the volume of waste requiring disposal. But today’s modern EfW facilities are designed to recover the value in the waste that remains after recycling energy and recyclables without harming the environment.

EfW facilities that recover energy from MSW in a specially designed boiler to ensure complete combustion and the recovery of energy. The energy recovery ? in the form of steam and electricity ? is then used for communities. EfW facilities also employ state of the art pollution control equipment to filter emissions for preventing their release into our environment.

EfW facilities supply reliable, base load renewable energy and divert waste from landfills, preventing methane emissions from decomposing garbage.

The incinerator burns solid waste 24 hours a day at a temperature of at least 850℃.

By incinerating the waste at such a high temperature, it suppresses the generation of dioxins. The ash remaining in the incinerator can be recycled as useful resources.

How combustible wastes are burned?

Combustible wastes are put into the waste pit by the garbage truck on the tipping hall. And then the waste will be incinerated until they turn into ashes in the incinerator.

Tipping hall

Garbage truck carries combustible wastes into the Tipping hall. Sheet shutter and air curtain are installed at the entrance to control the odor emission.

Incinerator

Incineration temperature above 850℃ restrain the generation of dioxin.

Boiler

High temperature gases can heat the water inside the pipes of the boiler and turn it into steam.

Air Quality

Pollutants in the exhaust gas are removed by exhaust gas treatment equipment such as bag filters, and clean gas that meets exhaust gas standards is emitted from the stack.

Monitoring and information disclosure

Central operation room

The operating state of the whole facility is managed by the central operation room 24 hours/day.

The amount of waste, combustion temperature, exhaust gas state, and power generation are monitored in real time.

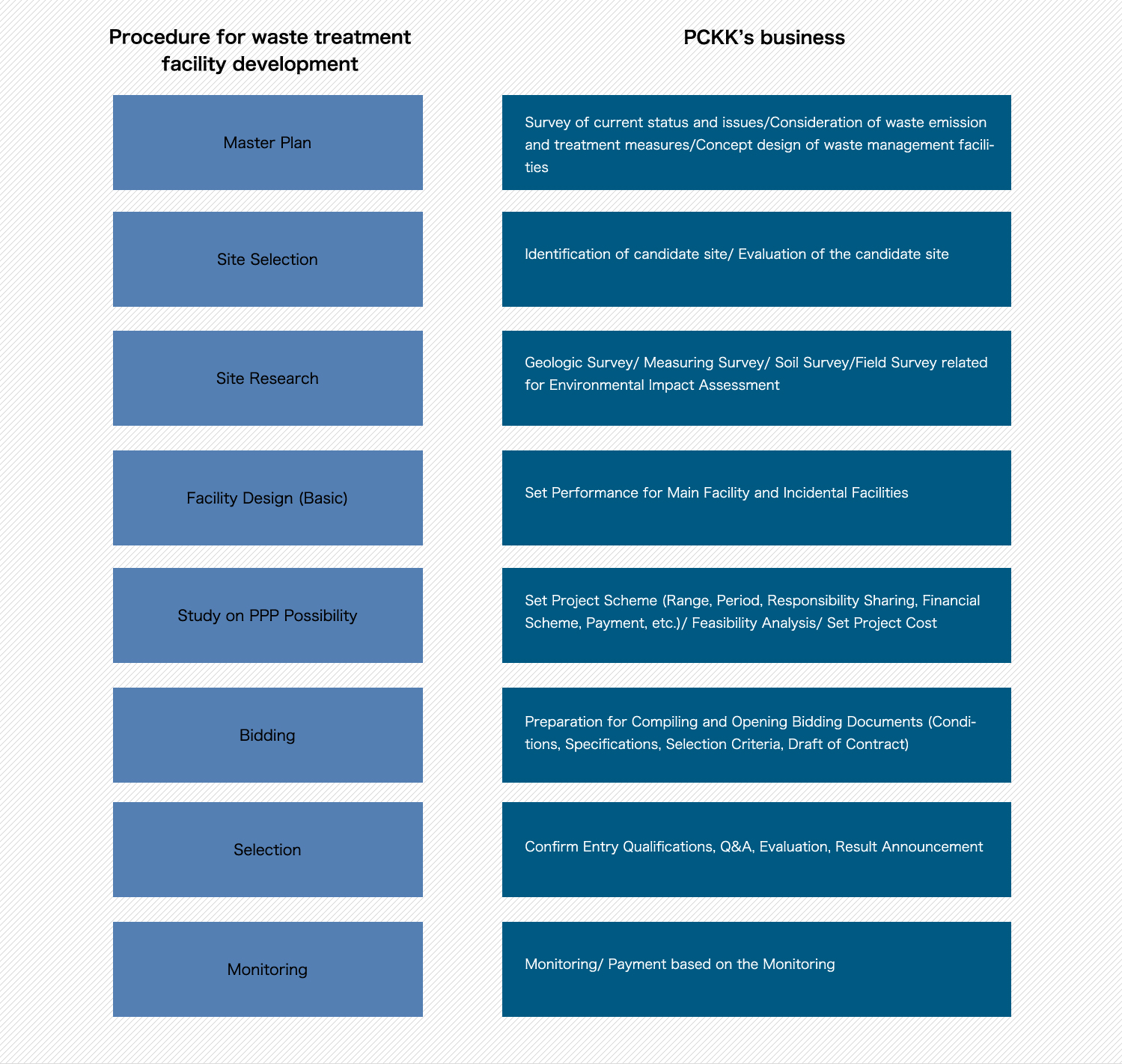

Waste Management Consulting

Pacific Consultants has been providing Services for Energy from Waste (EfW) Facilities.

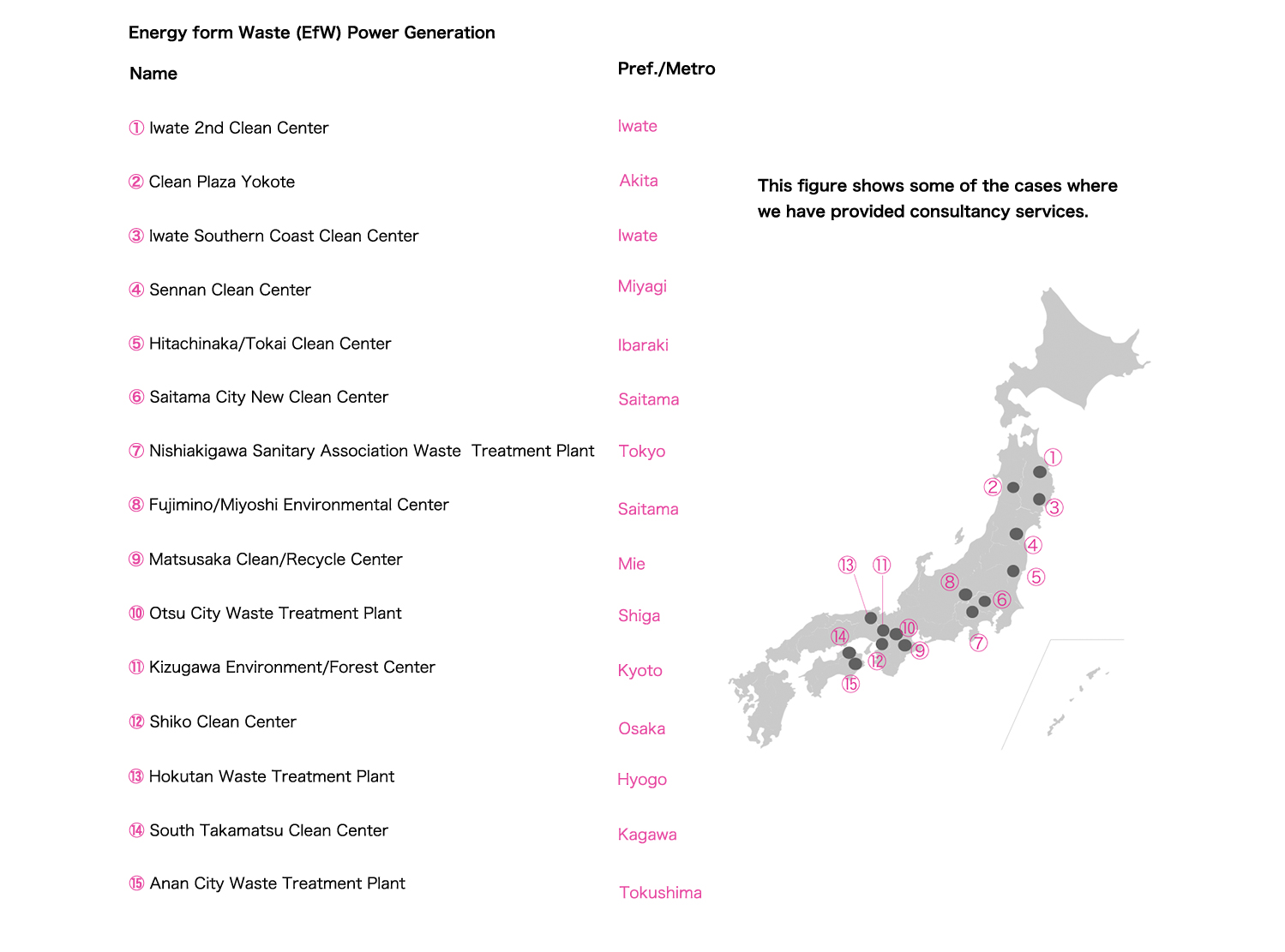

Management Consulting Services in Japan

Waste management projects cannot be interrupted due to their impact on the lives of residents.

Many local governments have found our consultancy services technically reliable and economically reasonable, and as a result, we have been involved in about 30% of the EfW projects that have been promoted as PPP projects in Japan in the past 10 years.

Energy from Waste Nagano Environmental Energy Center

| Capacity | Incinerators 405t/day (135t/day x 3) Ash melting furnace 22t/day Power generator 7,910kW |

|---|---|

| Service Provided | Construction Supervision |

| Project Cost | Roughly 36.7 billion Yen (Including operation and maintenance fee for 20 years) |

Energy from Waste Bari Clean

| Capacity | Incinerators 174t/day (87t/day x 2) Power generator 3,800kW |

|---|---|

| Service Provided | EIA, Support for Bidding, Construction Supervision, Operation monitoring |

| Project Cost | 11.9 billion Yen for Construction 9.3 billion Yen for operation and maintenance (20 years) |

| Evacuation Center | 320 citizens can be evacuated in the event of a disaster. |

| Emergency Generator | Supply power to the facility and evacuation center even during power outages caused by disasters. |

| Note | Japan Resilience Award 2019 (Strengthening Award) Grand Prix |

Pacific Consultants boasts an extensive track record in Japan and overseas as a pioneer in comprehensive construction consulting. Our consultants are ready to respond extensively based on the latest information to any questions from order placement representatives.